-

BIST 100

13821,97%0,49En Düşük13821,97En Yüksek0

13821,97%0,49En Düşük13821,97En Yüksek0 -

DOLAR

43,99%0,06Alış43,97Satış43,99En Yüksek43,99

43,99%0,06Alış43,97Satış43,99En Yüksek43,99 -

EURO

51,06%-0,73Alış51,05Satış51,06En Yüksek51,53

51,06%-0,73Alış51,05Satış51,06En Yüksek51,53 -

STERLİN

58,50%-0,79Alış58,48Satış58,50En Yüksek59,09

58,50%-0,79Alış58,48Satış58,50En Yüksek59,09 -

ALTIN

7600%-3,26Alış7313,21Satış7600En Yüksek7825

7600%-3,26Alış7313,21Satış7600En Yüksek7825

-

BIST 100

0%0,49En Düşük0En Yüksek0

0%0,49En Düşük0En Yüksek0 -

DOLAR

43,98%0,06Alış43,97Satış43,99En Yüksek43,99

43,98%0,06Alış43,97Satış43,99En Yüksek43,99 -

EURO

51,05%-0,73Alış51,05Satış51,06En Yüksek51,53

51,05%-0,73Alış51,05Satış51,06En Yüksek51,53 -

STERLİN

58,49%-0,79Alış58,48Satış58,50En Yüksek59,09

58,49%-0,79Alış58,48Satış58,50En Yüksek59,09 -

ALTIN

0%-3,26Alış7313,21Satış7600En Yüksek7825

0%-3,26Alış7313,21Satış7600En Yüksek7825

- Anasayfa

- Haberler

- Tüm Haberler

- Preparing for major price hikes

Preparing for major price hikes

Companies that are cutting profits will increase prices in 2014

1.10.2013 00:00:000

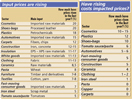

Over the last year, the prices of raw materials have increased considerably. Some inputs, such as processed leather, fibers and petrochemicals, have risen by over 15 per cent. But some producers have only been able to pass on half of these hikes, while others have been unable to pass them on at all... To put it another way, companies have been forced to make sacrifices. Some have given up on profits, while others have focused on productivity and reducing costs. But it does not look as if this situation will continue for long. Because phased price hikes are on the way in several sectors. Many sectors, such as furniture, carpets and shoes, are preparing to raise prices in 2014.

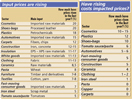

Click image to see the table.

PRICES HAVE SOARED

PRICES HAVE SOARED

Plastics heads the list of sectors where production costs have risen the most over the last year. The reason is the price of oil... Sem Plastik General Manager Yavuz Eroğlu says: “We have been affected a lot by the crises in the Middle East. Over the last year prices have risen by an average of 10 per cent, When you add the increase in the exchange rate then the rise in input costs reaches 18 per cent.”

Cosmetics is another of the sectors where input costs are rising to record levels. Neva Kozmetik Board Chair Armağan Okay says: “In a sector where imports account for 99 per cent, for cosmetics producers the turbulence on the markets has been reflected in an increase in prices. There have been increases of 20 per cent in both Turkish Lira and foreign exchange.” Ant Yapi Board Member Mehmet Okay explains input costs in the construction sector as follows: “Over the last year, labor costs have risen by 10 per cent, the cost of iron by 12 per cent and concrete by 15 per cent. For ongoing projects, it was only possible to raise prices by 5 per cent of these increases. To be honest, the market won’t accept any greater increase.”

NOT PASSED ON TO THE CONSUMER

It is not just in construction. The increases in costs are not being passed on to consumers in other sectors as well. The most important reason is the nature of competition. İpekyol Board Chair Yalçın Ayaydın says: “For the last two years we have been trying not to pass increases in costs onto the sales prices of products. Our retail prices have risen by the rate of inflation. But it is difficult to predict what will happen with prices in the future. Just because we have so far developed a strategy of not passing on increases, it does not appear possible to say that we shall do so in the future and that it will be this or that rate.”~

Another sector where the increase in costs is not being passed on to the consumer at the same rate is iron and steel. Veysel Yayan, the General Secretary of the Turkish Steel Producers’ Association, says that the reason for this is that there is oversupply on the global market. “In the world as a whole there is overcapacity of more than 500 million tons and, when global demand is weak, it is not possible to reflect all of the increase in raw material prices in product prices. But we forecast that in 2014, as a result of an increase in demand stemming from the expected upturn in the global economy, we shall be able to reflect on cost increases on prices, even if it is in stages.”

FALLING PROFITS!

All companies, regardless of the sector, are opting to avoid any decline in sales or market share during this critical process by “sacrificing profits”. So what are the results of an inability to pass on an 18 per cent increase in costs to the prices of final products and services? Of course, the most serious result is an erosion in profits...

Plastics is one of the sectors that is experiencing pressure on profits. Mehmet Uysal, the president of the Turkish Plastics Industrialists’ Research, Development and Training Foundation, (PAGEV) says: “As some of our companies in the plastics sector work from stock, there is no question of excessive losses at the moment. But, in order to avoid any damage from these increases that would have a negative impact on their competitiveness on international markets, our companies are reducing to a minimum any increase in prices as a result of a rise in input costs.”

THE ONLY WAY IS PRODUCTIVITY

So what is the solution? What kind of longterm strategy should be adopted by companies that are currently faced with low profits? How should they manage this process? Company executives are unanimous in answering “productivity.” For example, the Elvan Companies Group, which is one of the strongest players in the chocolate sector, is focusing on productivity. Hidayet Kadiroğlu, the chair of the company’s board, summarizes the measures they have implemented as follows:~

“The breadth of our product portfolio and the variety on our market provides price stability and we are protecting our cost advantage. But these factors will not allow us to go on like this forever. For this reason, we have established the first R&D center in our sector and brought more innovative products onto our agenda. Secondly, we are improving our processes and taking measures to increase productivity.”

Çilek Mobilya General Manager Muzaffer Çilek stresses the same points. “In response to the increases in costs, our most important strategies are working to improve processes and raising productivity,” he says, adding: “In this way we are removing activities that do not add any value from our processes. This enables us to reduce the amount by which we pass on price rises to our consumers.”

Click image to see the table.

PRICES HAVE SOARED

PRICES HAVE SOAREDPlastics heads the list of sectors where production costs have risen the most over the last year. The reason is the price of oil... Sem Plastik General Manager Yavuz Eroğlu says: “We have been affected a lot by the crises in the Middle East. Over the last year prices have risen by an average of 10 per cent, When you add the increase in the exchange rate then the rise in input costs reaches 18 per cent.”

Cosmetics is another of the sectors where input costs are rising to record levels. Neva Kozmetik Board Chair Armağan Okay says: “In a sector where imports account for 99 per cent, for cosmetics producers the turbulence on the markets has been reflected in an increase in prices. There have been increases of 20 per cent in both Turkish Lira and foreign exchange.” Ant Yapi Board Member Mehmet Okay explains input costs in the construction sector as follows: “Over the last year, labor costs have risen by 10 per cent, the cost of iron by 12 per cent and concrete by 15 per cent. For ongoing projects, it was only possible to raise prices by 5 per cent of these increases. To be honest, the market won’t accept any greater increase.”

NOT PASSED ON TO THE CONSUMER

It is not just in construction. The increases in costs are not being passed on to consumers in other sectors as well. The most important reason is the nature of competition. İpekyol Board Chair Yalçın Ayaydın says: “For the last two years we have been trying not to pass increases in costs onto the sales prices of products. Our retail prices have risen by the rate of inflation. But it is difficult to predict what will happen with prices in the future. Just because we have so far developed a strategy of not passing on increases, it does not appear possible to say that we shall do so in the future and that it will be this or that rate.”~

Another sector where the increase in costs is not being passed on to the consumer at the same rate is iron and steel. Veysel Yayan, the General Secretary of the Turkish Steel Producers’ Association, says that the reason for this is that there is oversupply on the global market. “In the world as a whole there is overcapacity of more than 500 million tons and, when global demand is weak, it is not possible to reflect all of the increase in raw material prices in product prices. But we forecast that in 2014, as a result of an increase in demand stemming from the expected upturn in the global economy, we shall be able to reflect on cost increases on prices, even if it is in stages.”

FALLING PROFITS!

All companies, regardless of the sector, are opting to avoid any decline in sales or market share during this critical process by “sacrificing profits”. So what are the results of an inability to pass on an 18 per cent increase in costs to the prices of final products and services? Of course, the most serious result is an erosion in profits...

Plastics is one of the sectors that is experiencing pressure on profits. Mehmet Uysal, the president of the Turkish Plastics Industrialists’ Research, Development and Training Foundation, (PAGEV) says: “As some of our companies in the plastics sector work from stock, there is no question of excessive losses at the moment. But, in order to avoid any damage from these increases that would have a negative impact on their competitiveness on international markets, our companies are reducing to a minimum any increase in prices as a result of a rise in input costs.”

THE ONLY WAY IS PRODUCTIVITY

So what is the solution? What kind of longterm strategy should be adopted by companies that are currently faced with low profits? How should they manage this process? Company executives are unanimous in answering “productivity.” For example, the Elvan Companies Group, which is one of the strongest players in the chocolate sector, is focusing on productivity. Hidayet Kadiroğlu, the chair of the company’s board, summarizes the measures they have implemented as follows:~

“The breadth of our product portfolio and the variety on our market provides price stability and we are protecting our cost advantage. But these factors will not allow us to go on like this forever. For this reason, we have established the first R&D center in our sector and brought more innovative products onto our agenda. Secondly, we are improving our processes and taking measures to increase productivity.”

Çilek Mobilya General Manager Muzaffer Çilek stresses the same points. “In response to the increases in costs, our most important strategies are working to improve processes and raising productivity,” he says, adding: “In this way we are removing activities that do not add any value from our processes. This enables us to reduce the amount by which we pass on price rises to our consumers.”

Türkiye ve dünya ekonomisine yön veren gelişmeleri yorulmadan takip edebilmek için her yeni güne haber bültenimiz “Sabah Kahvesi” ile başlamak ister misiniz?