- Anasayfa

- Haberler

- Tüm Haberler

- Cost hunters

Cost hunters

What is important here is the focus on the items that account for the lion’s share of costs...

1.09.2013 00:00:000

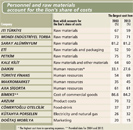

Effective cost management is one of the most critical issues for sustainable growth. For example, at Ford Otosan, which employs 10,000 people, the employees are responsible for cost management. It is not just Ford Otosan. Many companies which want to implement savings in tens of cost items, such as raw materials, personnel, energy and marketing, and are targeting sustainable growth are implementing significant programs in order to achieve this goal. Capital researched the largest cost items at companies ranging from Petkim to Axa Sigorta, Kale Kilit, Eti, Doğtaş and JTI. The result was a demonstration of how companies struggle with the items that account for the lion's share of their costs. Whatever the period, costs have always been at the top of companies’ agendas. The difference between today and the past lies in the approach to costs. Today, companies find and implement more innovative solutions rather than just trying to reduce the cost items. What is important here is the focus on the items that account for the lion’s share of costs...

Click image to see the table.

For example, at Ford Otosan, which employs 10,000 people, the employees are responsible for cost management. Ford Otosan General Manager Haydar Yenigün says that the projects developed by the product development and purchasing departments to reduce the costs of materials, which account for a large proportion of the company’s costs, have yielded very important results. It is estimated that in 2013 alone the cost-cutting measures will result in a saving of TL 200 million for the company.

For example, at Ford Otosan, which employs 10,000 people, the employees are responsible for cost management. Ford Otosan General Manager Haydar Yenigün says that the projects developed by the product development and purchasing departments to reduce the costs of materials, which account for a large proportion of the company’s costs, have yielded very important results. It is estimated that in 2013 alone the cost-cutting measures will result in a saving of TL 200 million for the company.

RAW MATERIALS ACCOUNT FOR THE LION'S SHARE

Raw materials costs account for a large proportion of the costs of many industrial companies. It is extremely difficult for companies in the iron and steel and chemicals industry to reduce their raw materials costs because it is the global markets which set commodity prices. But companies still use creative methods to find formulas to secure savings in these areas. One of these companies is Kale Kilit. Kale Endüstri Holding Deputy Board Chair Kenan Kiziltan says that materials and raw materials today account for 60 per cent of total costs. Kiziltan notes that the improvement measures that they have implemented have meant that costs have declined by four points compared with ten years ago.

PURCHASING FORMULAS

Many companies think that the most intelligent way to keep costs under control begins before purchasing. And they are intensifying the measures they are taking in this direction. One of these companies is Eti, where raw materials and packaging account for 50 per cent of total costs. Eti Companies Group CEO Hakan Polatoğlu says that this rate was 52 per cent in 2007. Polatoğlu adds: “Our suppliers have their own purchasing processes and stocking and distribution processes.~

We design these processes together with our suppliers. This enables us to design purchasing processes in a way that leads to improvements in quality and price. In this way, it is possible to create economies of scale in transportation and production processes. We secured savings of 2 percent like this in 2012.”

THE PROBLEM OF PERSONNEL EXPENSES

Personnel costs account for the lion’s share of costs for companies in the services sector in particular. One of these is Axa Sigorta, the insurance company. Axa Sigorta Board Member and Financial Affairs President Ayşegül Denli says that in 2012 personnel costs accounted for the highest proportion of general costs at 61 per cent. Denli says: “We work productively with a small number of highly qualified people but we provide the highest benefits in the market, For us, the concept of reducing personnel costs is a completely counter-productive mechanism. In the future our target will be the same as it is today, namely to benefit our employees even more.”

ENERGY SAVINGS

Energy costs are a significant burden for many companies. Kütahya Porselen Board Chair Nafi Güral says that over the last ten years energy costs have increased as a proportion of total costs instead of declining. Güral says that today electricity and natural gas costs account for 32 per cent of total costs, while ten years ago this figure was 26 per cent.

Petkim is a giant of the Turkish petrochemical sector. Raw materials account for 75 per cent of the company’s total costs. Energy costs account for another 8 per cent of Petkim’s costs. It was the same level ten years ago. Petkim General Manager Sadettin Korkut explains how they plan to reduce energy and raw material costs as follows: “In 2008 we invested approximately $100 million in converting our energy plant to natural gas, both for environmental reasons and to reduce our energy costs. We secured significant improvements.”

WHERE IS THE DIFFERENCE IN RETAILING?

Bimeks is one of the most important players in technology retailing and its largest cost item is the cost of commercial goods at 84.2 percent. Bimeks General Manager Arif Bayraktar says that in 2004 this figure was 86.6 percent and that over the last four years they have increased their turnover by an average of 30 per cent and developed their purchasing strengths and conditions.

Doğtaş is one of the leading retailers in Turkey and its biggest cost item is advertising and other marketing activities. Doğtaş Board Chair Davut Doğan says that ten years ago marketing costs accounted for 20 per cent of their total costs but that today the figure has fallen to 15 per cent. “As with every other expense item, as turnover increases there is a relative decline in our advertising expenditure,” Doğan explains. “Over the last year in particular we have implemented measures on issues such as greater efficiency in energy savings and logistics expenditure and we are reaping the benefits.”

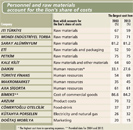

Click image to see the table.

For example, at Ford Otosan, which employs 10,000 people, the employees are responsible for cost management. Ford Otosan General Manager Haydar Yenigün says that the projects developed by the product development and purchasing departments to reduce the costs of materials, which account for a large proportion of the company’s costs, have yielded very important results. It is estimated that in 2013 alone the cost-cutting measures will result in a saving of TL 200 million for the company.

For example, at Ford Otosan, which employs 10,000 people, the employees are responsible for cost management. Ford Otosan General Manager Haydar Yenigün says that the projects developed by the product development and purchasing departments to reduce the costs of materials, which account for a large proportion of the company’s costs, have yielded very important results. It is estimated that in 2013 alone the cost-cutting measures will result in a saving of TL 200 million for the company.RAW MATERIALS ACCOUNT FOR THE LION'S SHARE

Raw materials costs account for a large proportion of the costs of many industrial companies. It is extremely difficult for companies in the iron and steel and chemicals industry to reduce their raw materials costs because it is the global markets which set commodity prices. But companies still use creative methods to find formulas to secure savings in these areas. One of these companies is Kale Kilit. Kale Endüstri Holding Deputy Board Chair Kenan Kiziltan says that materials and raw materials today account for 60 per cent of total costs. Kiziltan notes that the improvement measures that they have implemented have meant that costs have declined by four points compared with ten years ago.

PURCHASING FORMULAS

Many companies think that the most intelligent way to keep costs under control begins before purchasing. And they are intensifying the measures they are taking in this direction. One of these companies is Eti, where raw materials and packaging account for 50 per cent of total costs. Eti Companies Group CEO Hakan Polatoğlu says that this rate was 52 per cent in 2007. Polatoğlu adds: “Our suppliers have their own purchasing processes and stocking and distribution processes.~

We design these processes together with our suppliers. This enables us to design purchasing processes in a way that leads to improvements in quality and price. In this way, it is possible to create economies of scale in transportation and production processes. We secured savings of 2 percent like this in 2012.”

THE PROBLEM OF PERSONNEL EXPENSES

Personnel costs account for the lion’s share of costs for companies in the services sector in particular. One of these is Axa Sigorta, the insurance company. Axa Sigorta Board Member and Financial Affairs President Ayşegül Denli says that in 2012 personnel costs accounted for the highest proportion of general costs at 61 per cent. Denli says: “We work productively with a small number of highly qualified people but we provide the highest benefits in the market, For us, the concept of reducing personnel costs is a completely counter-productive mechanism. In the future our target will be the same as it is today, namely to benefit our employees even more.”

ENERGY SAVINGS

Energy costs are a significant burden for many companies. Kütahya Porselen Board Chair Nafi Güral says that over the last ten years energy costs have increased as a proportion of total costs instead of declining. Güral says that today electricity and natural gas costs account for 32 per cent of total costs, while ten years ago this figure was 26 per cent.

Petkim is a giant of the Turkish petrochemical sector. Raw materials account for 75 per cent of the company’s total costs. Energy costs account for another 8 per cent of Petkim’s costs. It was the same level ten years ago. Petkim General Manager Sadettin Korkut explains how they plan to reduce energy and raw material costs as follows: “In 2008 we invested approximately $100 million in converting our energy plant to natural gas, both for environmental reasons and to reduce our energy costs. We secured significant improvements.”

WHERE IS THE DIFFERENCE IN RETAILING?

Bimeks is one of the most important players in technology retailing and its largest cost item is the cost of commercial goods at 84.2 percent. Bimeks General Manager Arif Bayraktar says that in 2004 this figure was 86.6 percent and that over the last four years they have increased their turnover by an average of 30 per cent and developed their purchasing strengths and conditions.

Doğtaş is one of the leading retailers in Turkey and its biggest cost item is advertising and other marketing activities. Doğtaş Board Chair Davut Doğan says that ten years ago marketing costs accounted for 20 per cent of their total costs but that today the figure has fallen to 15 per cent. “As with every other expense item, as turnover increases there is a relative decline in our advertising expenditure,” Doğan explains. “Over the last year in particular we have implemented measures on issues such as greater efficiency in energy savings and logistics expenditure and we are reaping the benefits.”

Türkiye ve dünya ekonomisine yön veren gelişmeleri yorulmadan takip edebilmek için her yeni güne haber bültenimiz “Sabah Kahvesi” ile başlamak ister misiniz?