-

BIST 100

11340,10%0,00En Düşük11313,77En Yüksek11386,06

11340,10%0,00En Düşük11313,77En Yüksek11386,06 -

DOLAR

42,85%0,00Alış42,8412Satış42,8512En Yüksek42,8587

42,85%0,00Alış42,8412Satış42,8512En Yüksek42,8587 -

EURO

50,62%-0,01Alış50,6050Satış50,6350En Yüksek50,6555

50,62%-0,01Alış50,6050Satış50,6350En Yüksek50,6555 -

EUR/USD

1,18%-0,05Alış1,1773Satış1,1776En Yüksek1,1780

1,18%-0,05Alış1,1773Satış1,1776En Yüksek1,1780 -

ALTIN

6164,13%-0,11Alış6157,28Satış6170,99En Yüksek6172,59

6164,13%-0,11Alış6157,28Satış6170,99En Yüksek6172,59

-

BIST 100

11340,10%0,00En Düşük11313,77En Yüksek11386,06

11340,10%0,00En Düşük11313,77En Yüksek11386,06 -

DOLAR

42,85%0,00Alış42,8412Satış42,8512En Yüksek42,8587

42,85%0,00Alış42,8412Satış42,8512En Yüksek42,8587 -

EURO

50,62%-0,01Alış50,6050Satış50,6350En Yüksek50,6555

50,62%-0,01Alış50,6050Satış50,6350En Yüksek50,6555 -

EUR/USD

1,18%-0,05Alış1,1773Satış1,1776En Yüksek1,1780

1,18%-0,05Alış1,1773Satış1,1776En Yüksek1,1780 -

ALTIN

6164,13%-0,11Alış6157,28Satış6170,99En Yüksek6172,59

6164,13%-0,11Alış6157,28Satış6170,99En Yüksek6172,59

- Anasayfa

- Haberler

- Tüm Haberler

- Does the future lie in the outsourcers?

Does the future lie in the outsourcers?

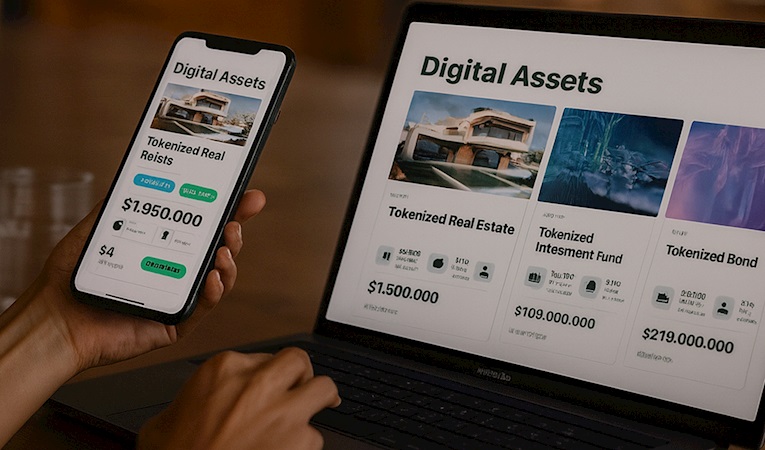

Today, the companies that are described as the new generation of outsourcers include global giants such as Hon Hai, Asustek etc

1.09.2009 00:00:000

The ASIAN companies which, during the 1990s, emerged from closed economies and used cheap labor to work as outsourcers have, over the last two years, used the know-how they acquired to become today’s manufacturing giants. They have moved from OEM (Original Equipment Manufacturing) to ODM (Original Design Manufacturing). The largest of this new generation of sub-contractors is Hon Hai of Taiwan which manufacturers 800,000 iPhone 3G telephones a week for Apple. At the end of 2008 the company’s turnover reached $60 billion. The next stage has been ODM manufacturers beginning to become powerful through their own brands.

WE CAN BE STRONG IN INDUSTRY

Fed Training Board Chair Prof. Dr. Arman K›r›m, who recommends that Turkish companies base their development strategy on the new generation of outsourcing, notes that Turkish are more likely to become strong through industrial outsourcing rather than the services outsourcing. “Turkey is not very talented when it comes to the global information technology sector,” says K›r›m. “We should not be looking for outsourcing in this sector. We have a much greater chance in the real sector. I do not believe we have any other chance except outsourcing.”

THE EVOLUTION OF OUTSOURCING

In Turkey, the pioneers of outsourcing production were the clothing and textile sectors. Since the 1990s it spread to the electronics, automotives, white goods, furniture, footwear, leather and machinery sectors. Until 15 years ago, many Turkish exporters used to manufacture by making exact copies of customer orders. The customers, which were global brands, would describe all the details of what they wanted and how they wanted it done. Turkish outsourcers would do the same. Those who started off like this, such as Zorlu Tekstil, Ye?im Tekstil, ‹mteks, Hey Tekstil, Rem Elektronik, Evyap, Karsan and Vestel, were the outsourcing giants of that time and have now become ODM manufacturers, or to put it another way, a new generation of outsourcers.

TURKS WHO ARE AN EXAMPLE TO THE WORLD

There are many successful ODM companies which have developed Turkey’s technology. Vestel is one of the largest ODM groups worldwide in consumer electronics. Around 50 percent of its exports consist of the new generation of outsourcing manufacturing. JVC, Hitachi, Toshiba, Sanyo, Whirlpool and Electrolux are just a few of the companies for which Vestel is an ODM. The multi-brand production strategy which Karsan adopted in 2002 means that today it is one of the leading private manufacturers both in Turkey and the world as a whole. Today, there is no other company in the world which, like Karsan, brings together five brands, including its own, under a single roof. It manufactures Renault Trucks Premium Long Haul, Premium Lander and Kerax, Peugeot Partner, Citroen Berlingo, Karsan J9 Premier and Hyundai Truck HD Series models.

THE PERFORMANCE OF TURKEY’S RIVALS

There are many countries which are Turkey’s rivals in terms of outsourcing production in different sectors. These countries are ahead of Turkey in many sectors when it comes to rates of outsourcing production. For example, outsourcing accounts for approximately 60 percent of Turkey’s leather clothing and leather goods exports. In China, India and Pakistan, which are similar to Turkey, the rate rises to 95 percent. Outsourcing production accounts for a maximum of 60 percent of manufacturers’ exports in white goods, while in similar countries such as Taiwan, South Korea, China and India this rate is 60-70 percent. In clothing and household textiles both in Turkey and in China, Pakistan, Indonesia, Bangladesh, Malaysia and India outsourcing accounts for approximately 95 percent of exports.

DO INVESTMENTS IN THE BRAND ERODE PROFITS?

For the last 15 years Turkish companies have been always thinking about the idea of creating a global brand. Now they are beginning to see the new generation of outsourcing as an alternative. Burç Cemilo€lu, the owner of ‹mteks which produces _45 million of new generation outsourcing per year for brands such as Adidas, Nike and Tommy Hilfiger, notes that the new generation of outsourcing has enabled them to increase both their turnover and profitability even in times of crisis. Cemilo€lu says that developing a brand and realizing exports is a very expensive, risky and individual business. He adds that neither are there important differences in terms of profitability between outsourcing and brand exports.

WE CAN BE STRONG IN INDUSTRY

Fed Training Board Chair Prof. Dr. Arman K›r›m, who recommends that Turkish companies base their development strategy on the new generation of outsourcing, notes that Turkish are more likely to become strong through industrial outsourcing rather than the services outsourcing. “Turkey is not very talented when it comes to the global information technology sector,” says K›r›m. “We should not be looking for outsourcing in this sector. We have a much greater chance in the real sector. I do not believe we have any other chance except outsourcing.”

THE EVOLUTION OF OUTSOURCING

In Turkey, the pioneers of outsourcing production were the clothing and textile sectors. Since the 1990s it spread to the electronics, automotives, white goods, furniture, footwear, leather and machinery sectors. Until 15 years ago, many Turkish exporters used to manufacture by making exact copies of customer orders. The customers, which were global brands, would describe all the details of what they wanted and how they wanted it done. Turkish outsourcers would do the same. Those who started off like this, such as Zorlu Tekstil, Ye?im Tekstil, ‹mteks, Hey Tekstil, Rem Elektronik, Evyap, Karsan and Vestel, were the outsourcing giants of that time and have now become ODM manufacturers, or to put it another way, a new generation of outsourcers.

TURKS WHO ARE AN EXAMPLE TO THE WORLD

There are many successful ODM companies which have developed Turkey’s technology. Vestel is one of the largest ODM groups worldwide in consumer electronics. Around 50 percent of its exports consist of the new generation of outsourcing manufacturing. JVC, Hitachi, Toshiba, Sanyo, Whirlpool and Electrolux are just a few of the companies for which Vestel is an ODM. The multi-brand production strategy which Karsan adopted in 2002 means that today it is one of the leading private manufacturers both in Turkey and the world as a whole. Today, there is no other company in the world which, like Karsan, brings together five brands, including its own, under a single roof. It manufactures Renault Trucks Premium Long Haul, Premium Lander and Kerax, Peugeot Partner, Citroen Berlingo, Karsan J9 Premier and Hyundai Truck HD Series models.

THE PERFORMANCE OF TURKEY’S RIVALS

There are many countries which are Turkey’s rivals in terms of outsourcing production in different sectors. These countries are ahead of Turkey in many sectors when it comes to rates of outsourcing production. For example, outsourcing accounts for approximately 60 percent of Turkey’s leather clothing and leather goods exports. In China, India and Pakistan, which are similar to Turkey, the rate rises to 95 percent. Outsourcing production accounts for a maximum of 60 percent of manufacturers’ exports in white goods, while in similar countries such as Taiwan, South Korea, China and India this rate is 60-70 percent. In clothing and household textiles both in Turkey and in China, Pakistan, Indonesia, Bangladesh, Malaysia and India outsourcing accounts for approximately 95 percent of exports.

DO INVESTMENTS IN THE BRAND ERODE PROFITS?

For the last 15 years Turkish companies have been always thinking about the idea of creating a global brand. Now they are beginning to see the new generation of outsourcing as an alternative. Burç Cemilo€lu, the owner of ‹mteks which produces _45 million of new generation outsourcing per year for brands such as Adidas, Nike and Tommy Hilfiger, notes that the new generation of outsourcing has enabled them to increase both their turnover and profitability even in times of crisis. Cemilo€lu says that developing a brand and realizing exports is a very expensive, risky and individual business. He adds that neither are there important differences in terms of profitability between outsourcing and brand exports.

Türkiye ve dünya ekonomisine yön veren gelişmeleri yorulmadan takip edebilmek için her yeni güne haber bültenimiz “Sabah Kahvesi” ile başlamak ister misiniz?